Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

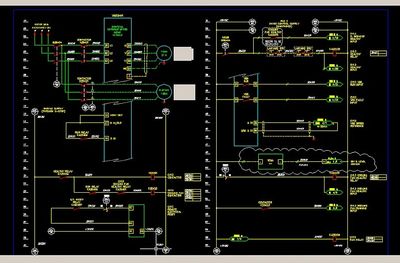

We know how chaotic the manufacturing floor can get. Especially in the "heat of battle" when you have to use a different part, add a relay to the system, etc. Before someone can get to updating the print to get a nice new UPDATED copy, you are onto the next problem. Let us be the AutoCAD grunts that keep your prints updated. A clean and CORRECT print will save countless downtime.

Our team of skilled electrical engineers provides CAD drawings from your Napkin and whiteboard sketches. We can calculate the engineering requirements of the system such as FLA ratings, VFD parameters, circuit protection, etc.

For when you receive a new piece of equipment, a point to point is heavily recommended. Majority of OEMs build a "template" of a machine with some level of customization based on your plant's requirements. Sometimes, the electrical print is overlooked on the component and wire label basis. A point to point at the FAT or shortly after can catch an issue before it is a problem. You do not want to find yourself troubleshooting a print during unplanned downtime. We can give you the comfort of trusting an electrical schematic on a new piece of equipment.

We offer training and education services for our clients, providing them with the knowledge and skills they need to operate and maintain their electrical systems. This includes the basics of opening an AutoCAD print, drawing components, some quick shortcuts and generating pages/pdfs from a .dwg file. Our team is dedicated to helping our clients achieve their goals and succeed in their industries.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.